Senawang Laminating Technologies has been certified for ISO 9001 standards. The laminates have been approved by US Navy for Mil Standard -- Mil PRF 81705 Type III. Senawang Laminating Technologies have registered with FDA with Drug Master File (DMF) number 19108.

The product quality is of paramount importance to Senawang Laminating Technologies. A fully staffed and equipped quality assurance laboratory complements the production capabilities. The results from the QA tests are used to further refine the products and processes. Customers may also elect to have either Certificates of Compliance or Certificates of Analysis included with every shipment. Feedback from customers is always welcome and seen as path for improvement.

Our current test capabilities cover three main areas: physical, electrical and chemical characteristics.

|

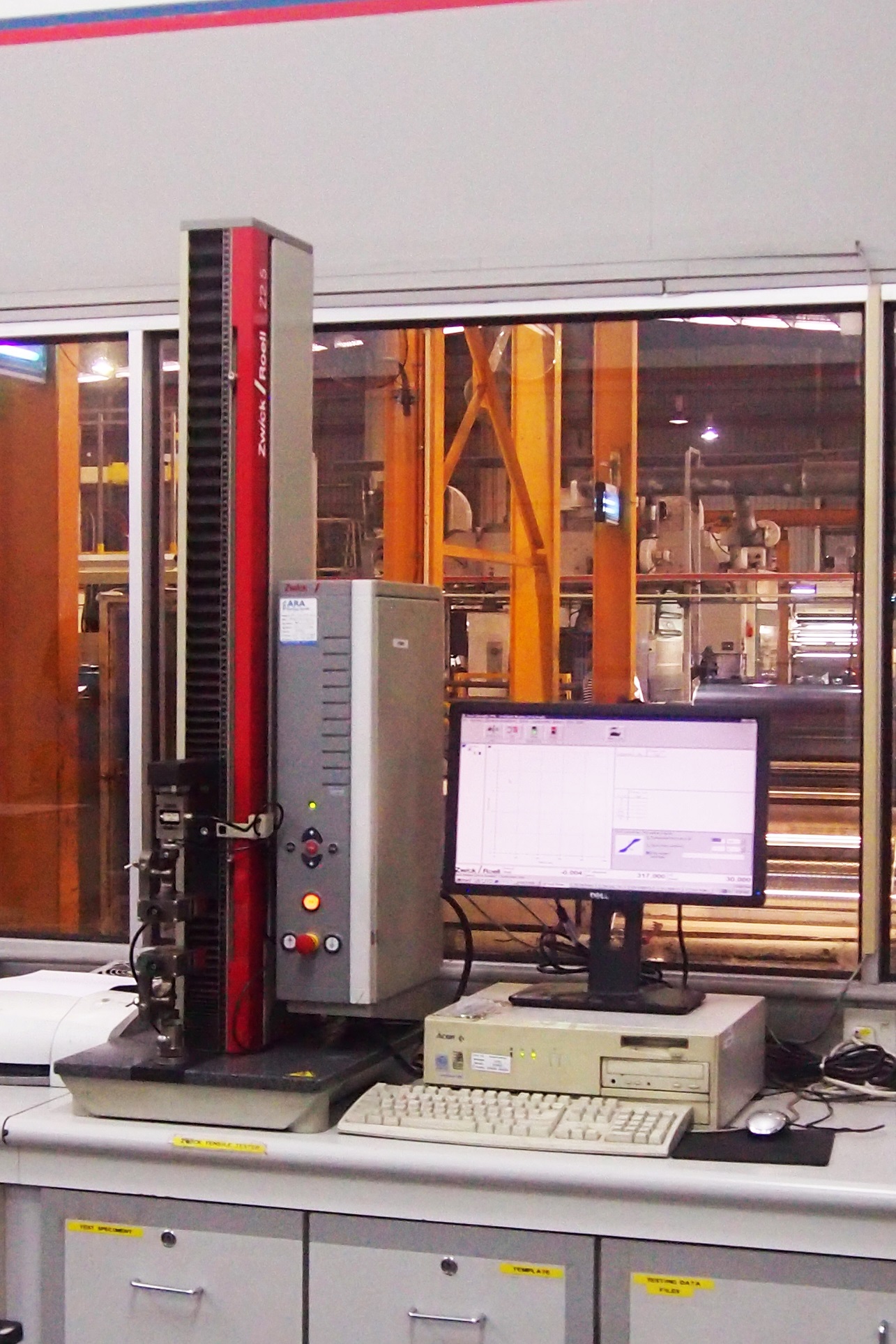

The tester is computer controlled and capable of performing a wide variety of tests. Tensile strength test, elongation test, puncture resistance test and seal strength test are just few examples. |

|

|

Universal Tensile Tester

|

|

|

|

|

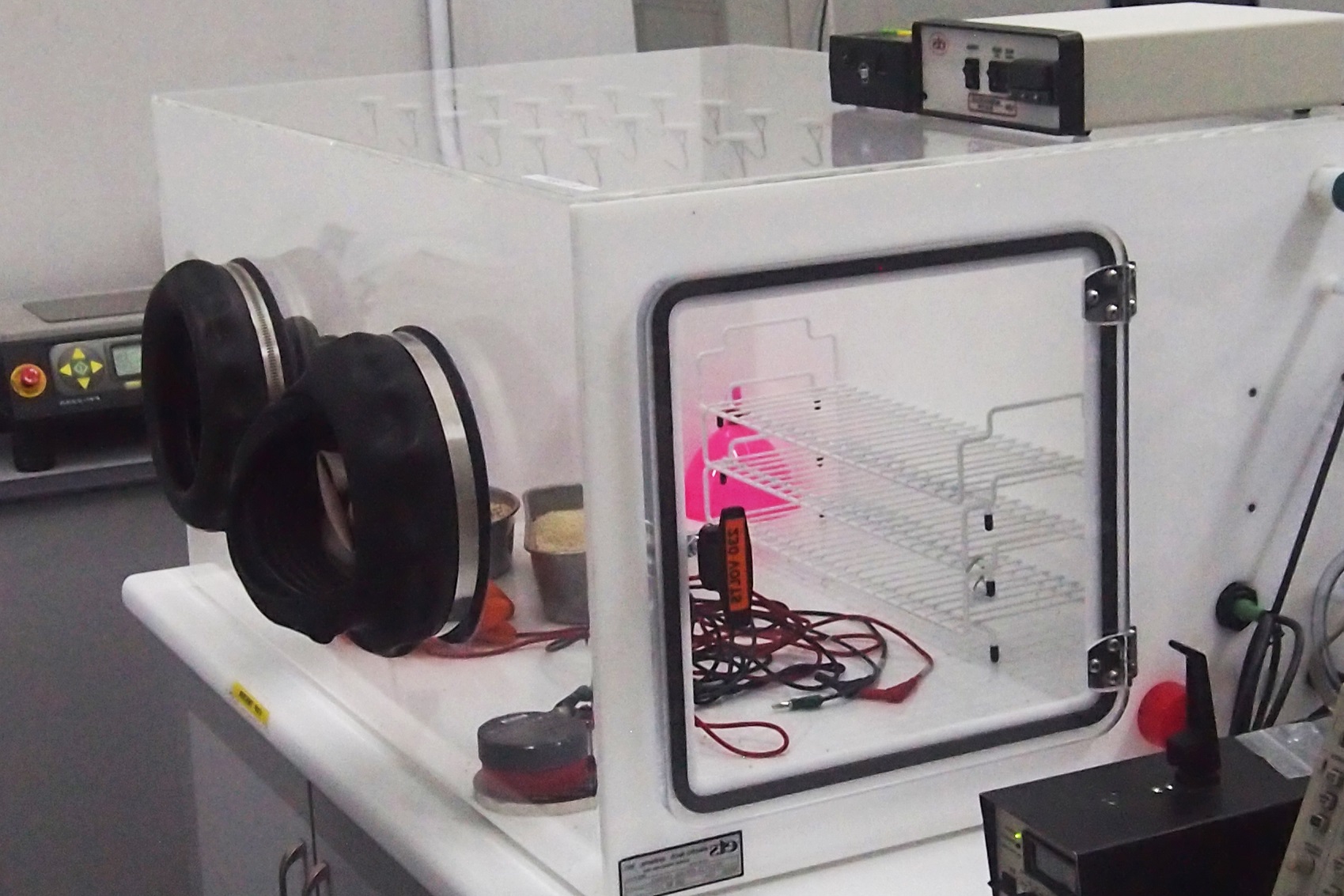

The Dry Box is used to test electrical properties such as surface resistance under low humidity conditions.

|

The EOS/ ESD Energy Test apparatus is used to measure the ESD shielding capability of laminates.

|

|